A Method of Thermal Management for High Power PCB

The whole power electronics industry, including RF applications and systems involving high-speed signals, is developing towards solutions that provide more and more complex functions in smaller and smaller spaces. Designers are facing more and more rigorous challenges in meeting the requirements of system size, weight and power, including effective heat management, which starts from the design of PCB.

Active power devices with high integration (such as MOSFET transistors) will emit a lot of heat, so PCB is required to transfer heat from the hottest components to the ground or heat dissipation surface, so as to operate as efficiently as possible. Thermal stress is one of the main causes of power device failure, because it will lead to performance degradation, and even may lead to system failure or failure. The rapid growth of device power density and continuous improvement of frequency are the main reasons for overheating of electronic components. Although semiconductors with lower power loss and better thermal conductivity, such as wide band gap materials, are used more and more widely, they are not enough to eliminate the need for effective heat management.

At present, the achievable junction temperature of silicon based power devices is between 125 ℃ and 200 ℃. However, it is better to keep the device working within this limit condition, so as to avoid rapid aging of the device and shorten its remaining life. In fact, it is estimated that if the working temperature rises by 20 ℃ due to improper heat dissipation management, the remaining life of components will be reduced by as much as 50%.

layout method

The heat dissipation management method commonly used in many projects is to use the substrate with standard flame retardant grade 4 (FR-4), which is a cheap and easy to process material and focuses on the heat dissipation optimization of circuit layout.

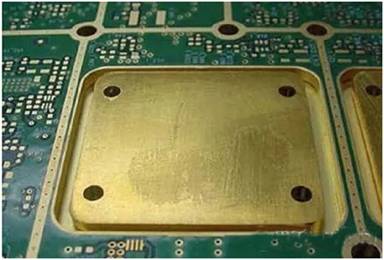

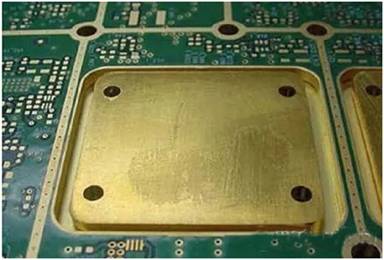

The main measures involved providing additional copper surfaces, using thicker cabling, and inserting heat dissipation holes under the components that generated the most heat. A more radical technology that can emit more heat, including inserting a real copper block into a PCB or applying it to the outermost layer, which is usually in the shape of a coin, hence the name "copper coin". After the copper coins are processed separately, they can be welded or directly attached to the PCB, or inserted into the inner layer and connected with the outer layer through the heat dissipation hole. A special cavity is made in the PCB shown in Figure 1 to hold a copper coin.

PCB with copper coins

The thermal conductivity of copper is 380W/mK, that of aluminum is 225W/mK, and that of FR-4 is 0.3W/mK. Copper is a relatively cheap metal, which has been widely used in PCB manufacturing; As a result, it is ideal for making copper coins, cooling holes and strata - all of these solutions can improve heat dissipation.

The correct placement of active components on the circuit board is the key factor to prevent the formation of hot spots, so as to ensure that the heat is distributed as evenly as possible on the entire circuit board. In this regard, active devices should be distributed around the PCB in a different order to avoid hot spots in specific areas. However, it is better to avoid placing active devices that generate a lot of heat near the edge of the circuit board. On the contrary, they should be placed as close to the center of the circuit board as possible to facilitate uniform heat distribution. If high-power devices are installed near the edge of the circuit board, heat will accumulate at the edge, thus increasing local temperature. On the other hand, if it is placed near the center of the circuit board, the heat will be emitted along the surface in all directions, which makes the temperature easier to reduce and the heat easier to emit. Power devices shall not be placed close to sensitive components and shall be properly spaced from each other.

The measures taken at the layout level can be further improved by using active cooling and passive cooling systems (such as radiators or fans) - such systems can remove heat from active components rather than emitting it directly to the circuit board. Generally speaking, designers must find an appropriate compromise between different cooling management strategies according to the requirements of specific applications and available budgets.

PCB base plate selection

FR-4 is generally not suitable for applications that need to emit a lot of heat due to its low thermal conductivity (between 0.2 and 0.5W/mK). The heat generated in high-power circuits may be considerable, and these systems often operate in harsh environments and extreme temperatures. Compared with the traditional FR-4, the alternative substrate material with higher thermal conductivity may be a better choice.

For example, ceramic materials provide significant advantages for heat management of high-power PCB. In addition to improving thermal conductivity, these materials also have excellent mechanical properties, thus helping to compensate for the stress accumulated during repeated thermal cycles. In addition, ceramic materials have low dielectric loss at frequencies up to 10GHz. For higher frequencies, it is always possible to choose a mixed material (such as PTFE), which can provide the same low loss, but with a moderate reduction in thermal conductivity.

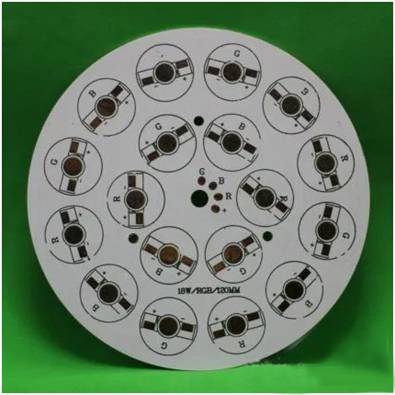

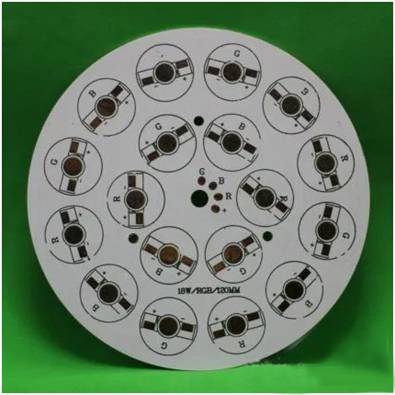

The higher the thermal conductivity of the material, the faster the heat transfer. Therefore, in addition to being lighter than ceramics, aluminum and other metals also provide an excellent solution that can transfer heat from components. In particular, aluminum is an excellent conductor with excellent durability, recyclability and non-toxic. Because of the high thermal conductivity, the metal layer helps to transfer heat quickly throughout the circuit board. Some manufacturers also provide metal clad PCBs, two of which are metal clad, usually aluminum or galvanized copper. From the perspective of unit weight cost, aluminum is the best choice, while copper has higher thermal conductivity. Aluminum is also widely used to manufacture PCB that support high-power LED (as shown in the example in Figure 2), where its ability to reflect light off the substrate is particularly useful.

Example of aluminum PCB for high-power RGB LED

Even silver, because its thermal conductivity is about 5% higher than copper, can also be used to make wires, through holes, pads and metal layers. In addition, if the circuit board is used in a humid environment with toxic gases, the use of silver trim on exposed copper wires and copper pads will help prevent corrosion - a typical threat known in such environments.

Metal PCB, also known as insulating metal substrate (IMS), can be directly laminated into PCB to form a board with FR-4 substrate and metal core. The single-layer and double-layer technologies are adopted, and the depth control wiring is provided, so that the heat can be transferred from on-board components to less important areas. In IMS PCB, a thin layer of conductive but electrically insulated dielectric is laminated between the metal substrate and the copper foil. The copper foil is etched into the desired circuit pattern, and the metal substrate absorbs heat from the circuit through the thin dielectric.

The IMS PCB provides the following main advantages:

·The heat dissipation is obviously higher than the standard FR-4 structure.

·The thermal conductivity of the dielectric is usually 5 to 10 times higher than that of ordinary epoxy glass.

·The efficiency of heat transfer is much higher than that of traditional PCB.

In addition to LED technology (lighting signs, displays and lighting), IMS circuit boards are also widely used in the automotive industry (headlamp, engine control and power steering), power electronics (DC power supply, inverter and engine control), switches, semiconductor relays and other fields.