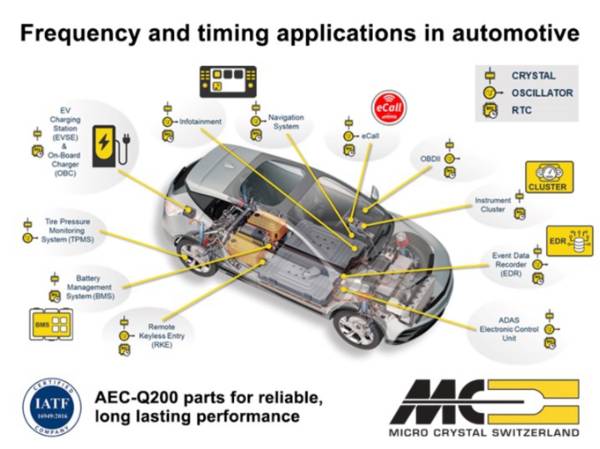

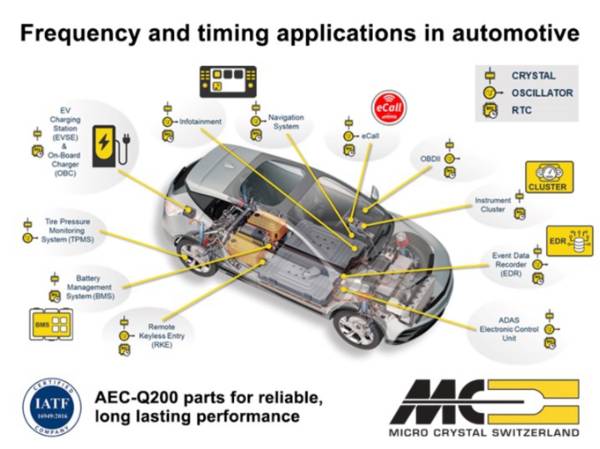

Micro Crystal Swiss microcrystals are widely used in timing and frequency products in the automotive industry

Micro Crystal Swiss microcrystals are widely used in timing and frequency products in the automotive industry

At present, the timing function is a key requirement in various types of data recorder products in a large number of automotive applications. Especially for driving data recorders (EDR), diagnostic systems (OBDII), instrument clusters, and infotainment systems, the timing function is particularly important. In recent years, with the rise of car electrification, the timing function has been widely used in electric vehicle charging systems (EVSE, OBC) and battery management systems (BMS).

When you enter your car, more than a hundred hidden clock devices inside the car begin to work, monitoring the car's performance in real-time, ensuring driving safety, and allowing you to enjoy comfort and convenience during the journey.

For any electronic device, whether it is consumer electronics, IoT devices, or electronic devices in industrial, medical, or automotive subsystems, timing technology is at its core.

At present, the timing function is a key requirement in various types of data recorder products in a large number of automotive applications. Especially for driving data recorders (EDR), diagnostic systems (OBDII), instrument clusters, and infotainment systems, the timing function is particularly important. In recent years, with the rise of car electrification, the timing function has been widely used in electric vehicle charging systems (EVSE, OBC) and battery management systems (BMS). When the GPS automatic time setting function is not activated or the GPS signal is lost, in order to avoid customer complaints and conduct necessary analysis (black box), the timing function is inevitably used, so this function is very important.

Automotive applications require a large operating temperature range, typically between -40 ° C and+125 ° C. Weather conditions and the heat generated by the engine or battery pack can cause significant temperature fluctuations in the electronic systems of cars, which may reduce the accuracy of timing components.

In order to achieve the time accuracy requirement defined as the daily time deviation, it is necessary to compensate for the 32.768kHz oscillator at this time. After market validation, the most effective method is to use a real-time clock (RTC) module with an embedded temperature compensated oscillator (TCXO).

RV-3032-C7 Real Time Clock Module in BMS

Like many other applications, in BMS applications, in order to achieve the function of a black box, we also use real-time clock (RTC) and memory. In this way, RTC can provide accurate timestamps, while memory can be used to store data collected from battery cell sensors (temperature, voltage, current, etc.). To evaluate the charging state (SoC) and health state (SoH) of a battery pack, it is necessary to base them on time related information. The accuracy and reliability of these values are crucial for determining the remaining range of a vehicle, as well as for diagnosing and taking necessary corrective measures, or triggering fault protection mechanisms to ensure the health of the battery pack.

RV-3032-C7 can provide temperature compensation at ± 2.5 ppm (± 0.22s/day) in the AEC-Q level 3 temperature range (-40 ° C to+85 ° C), always maintaining optimal accuracy; In addition, RV-3032-C7 also has an ultra-low current consumption of 160nA. This high-performance RTC has multiple functions. For the development of automotive applications, an innovative and very useful feature is the precise (± 1 ° C) embedded high-resolution (12 bit) temperature sensor. It has a programmable temperature window detection interrupt function, which can provide a timestamp for temperature alarm events, making it an ideal choice for thermal runaway detection or rapid temperature change detection. In addition, the device has a 1-second refresh cycle and can provide real-time temperature monitoring. When the temperature exceeds the specified range, it will wake up the main module MCU to trigger an alarm. This function ensures proper operation even when the electric vehicle is inactive or not plugged in. The added ultra-low power and continuous temperature monitoring functions in the system also provide redundant options for the system architecture, helping to ensure that the design meets the requirements of ISO 26262 ASIL * standards.

Compliance with the AEC-Q200 standard ensures that automotive manufacturers' quartz based timing components meet the resistance requirements related to automotive, temperature, vibration, and impact tasks.

By integrating quartz crystals and temperature sensors into ultra small RTC packages, their volume can be minimized to the greatest extent possible.

RV-3032-C7 is a calibrated device that can simplify the manufacturing process, requiring only single point temperature verification.

In addition, it can be easily connected through the same I2C bus used by other sensors and hardware devices.

This RTC has extremely high time accuracy at the factory, eliminating the hassle of oscillator design, phase adjustment, and clock calibration during the manufacturing process. If you choose and use ready-made RTC module solutions in your design, you can reduce the workload of designing products, reduce risks, and bring innovation to the automotive industry, improving customer satisfaction.

Micro Crystal is a Swiss company that understands the essence of timing product design, and its timing and frequency product lines can meet the extreme requirements of product size, power consumption, and performance; The company will continue to be committed to helping engineers develop next-generation automotive equipment and other intelligent products. The company's products cover a wide range of compact applications, such as measurement solutions, POS, automation, health and medical devices, wearable devices, etc.